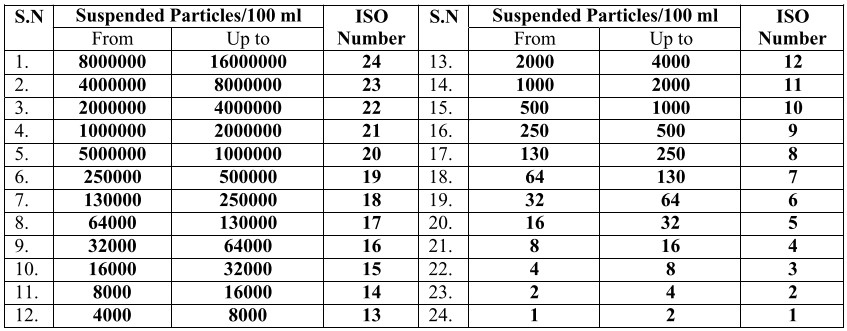

ISO4406:1999 standard determines the quantity of particles in a cumulative way. i.e. >4µm, > 6 µm >14µm by using particle counter and assigns characteristic (code) number to them. Contamination level of assignments to particle numbers is to facilitate the assessments of purity of fluid. 100 ml sample taken is defined in terms of number of suspended particles as per table below.

Sudden breakdown in an oil system is often caused by large particles (>14µ) in the oil while slower, progressive faults, like wear and tear are caused by the smaller particles (4-6 µ).

Particle reference sizes are set to 4 µm, 6µm and 14µm in ISO 4406:1999 for classification of hydraulic oil.